Refrigerated butter and margarine are hard, applying a burden to machines and making it difficult to mix with a mixer. Therefore, it is necessary to bring it back to room temperature.

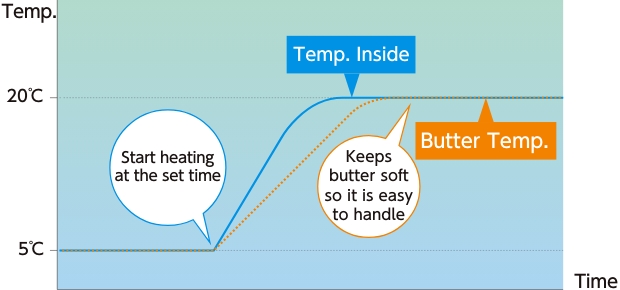

Hot water and fermenters are often used to quickly bring butter and margarine back up to working temperature, however using these methods requires additional time consuming steps such as breaking butter into smaller portions. Using an MK Food Temperature Control Cabinet greatly reduces the overall time and effort required to return butter and margarine to working temperature by storing the ingredients in more appropriate conditions.